|

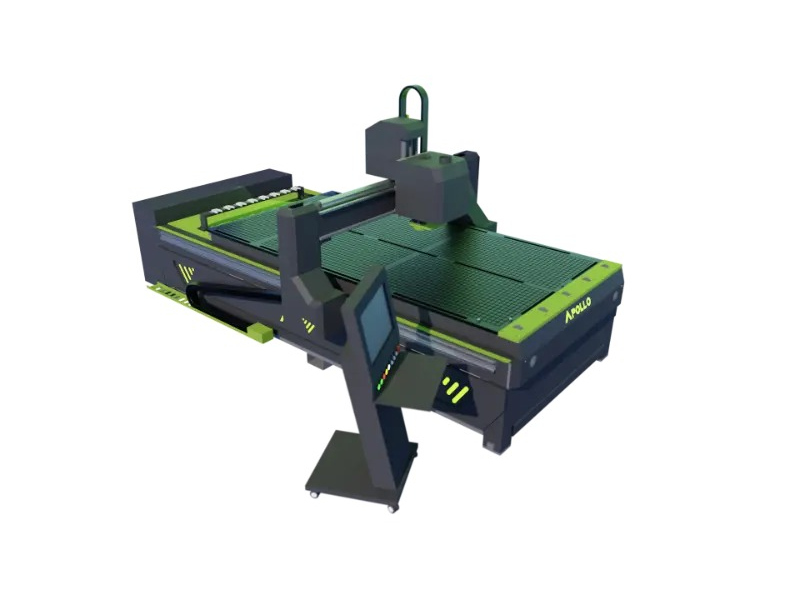

Unrivalled Control System |

In-house developed M-TECH motion control that includes a Touch based PC-based system, wireless pendant and podium. |

|

High-performance spindles |

9.0KW (12hp) ER32 air cooled spindle system 24,000rpm with automatic tool change function. 8 x ISO 30 tool holders/positions. |

|

Mechanical drive |

Helical rack and pinion, reciprocating ball screw drives on Z. |

|

Drive system |

Delta servo drive system – exceptional performance with lower power consumption |

|

Linear guide rails/carriers |

HIWIN oil inject centralised linear rail lubrication. |

|

Material Positioning Stops/Guides |

Pneumatic pop-up end stops for material location. |

|

Vacuum system |

Yes – Multi-zone matrix bed with touch screen activation controls, including pump system and filter. |

|

Extraction system |

Enhanced, ‘Focused’ dust extraction system included. |

|

Tool cooling |

Integrated pneumatic cutter cooling/lubrication system. |

|

Safety features |

Modular Safety fences with optical IR guarding. |

|

Software package |

M-TECH Control & we advice Vectric V Carve Pro (Optional AlphaCAM) |

|

Installation |

Our professional installation team will fully commission your new machine – It is the customers responsibility to ensure they have the correct electrical and air outputs (we will advise you on what is required). |