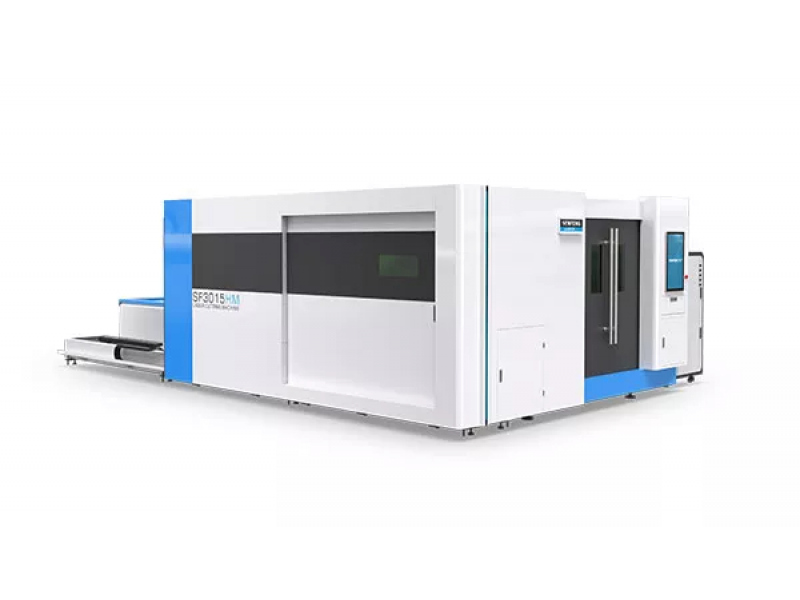

The SENFENG 3015HM is a highly efficient and precise metal cutting machine, adept at cutting both sheets and pipes with exceptional stability and reliability. It incorporates a high-quality mechanical structure and electrical components, ensuring stable operation over extended periods while minimising the rate of failure.

The SENFENG 3015HM is a highly efficient and precise metal cutting machine, adept at cutting both sheets and pipes with exceptional stability and reliability. It incorporates a high-quality mechanical structure and electrical components, ensuring stable operation over extended periods while minimising the rate of failure.

This equipment is extensively applicable in various sectors, including metal processing, machinery manufacturing, automobile production, and aerospace, making it a versatile tool in these industries.

| Specification | Item |

|---|---|

| Model Name | SF3015HM |

| Laser Power (kW) | 1.5kW | 3kW | 6kW |

| Working Area (mm) | 3050*1530 | 4050*2030 | 6050*1530 | 6050*2030 | 6050*2530 |

| Positioning Accuracy | ±0.05mm |

| Max Speed | 130 m/min |

| Max Acceleration | 1.0G |

| Overall Dimensions | 8330*3910*2260mm |

| Safety Enclosure | Included |

| Rotary Indexer | 6000 mm Tube Cutting |

In terms of technology, the SENFENG 3015HM leverages advanced laser cutting technology, which offers unparalleled precision and speed. This technology enables businesses to achieve higher productivity and efficiency in their operations. With its ability to handle a range of materials and thicknesses, the machine is ideal for custom or large-scale production runs.

Moreover, the use of high-quality components not only ensures the machine’s longevity but also reduces maintenance costs over time. The fast shuttle exchange table allows for quick loading and unloading of materials, further enhancing production efficiency. The range of cutting powers available means that businesses can select the most appropriate configuration for their specific needs, whether they are cutting thin sheets or thick tubes.

The fully enclosed design is another significant advantage, ensuring the safety of operators by containing hazardous vapours and laser radiation. This feature makes it compliant with workplace safety regulations, reducing the risk of accidents and liability for businesses.