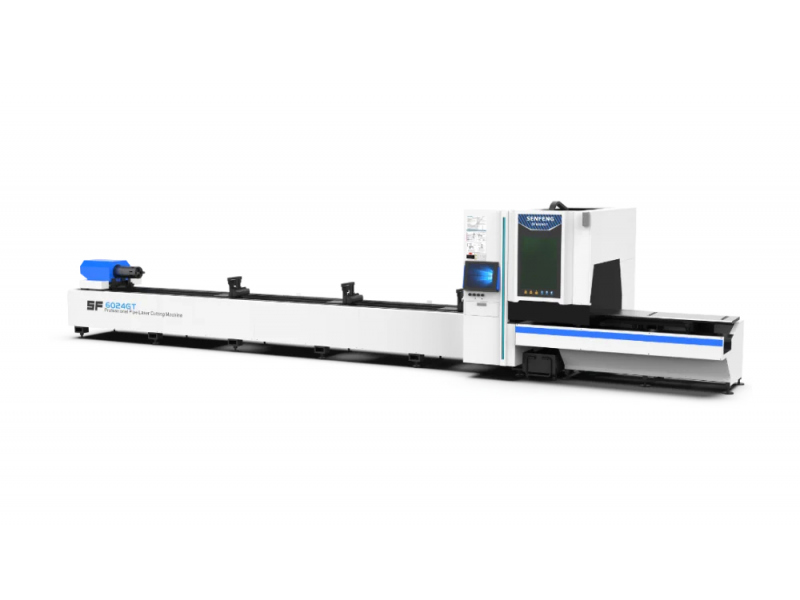

Our Bevel Fibre Laser Tube Cutter revolutionises pipe cutting with its ability to perform high-quality 45° bevel cuts, reducing the need for separate beveling operations.

It features pneumatic chucks for auto clamping that ensure stable and precise cutting, adaptable to various pipe shapes. With flexible floating support wheels and an advanced bevel laser cutting system, it supports high-precision cutting of diverse pipe shapes, maximizing efficiency and minimizing waste.

This machine is a game-changer for industries requiring precise bevel cutting, such as petroleum, chemical, shipbuilding, and construction, enhancing sealing, safety, and structural integrity of pipe connections.

It’s possible to achieve bevel cuts of up to ±45°, eliminating the need for additional beveling steps in the manufacturing process.

| Specification | Item |

|---|---|

| Model Name | SF6024GT |

| Laser Power (kW) | 3kW | 4kW | 6kW |

| Pipe Processing Range(Round Tube) | φ10-φ230mm |

| Pipe Processing Range(Square Tube) | 10×10-230×230mm |

| Max Speed | 75 m/min |

| Positioning Accuracy | ±0.05 |

| Repeated Positioning Accuracy | ±0.03mm |

| Max chuck Speed | 100r/min |

| Max Acceleration | 0.8G |

| Max Table Load | 250KG |

| Specification | Item |

|---|---|

| Model Name | SF6035GT |

| Laser Power (kW) | 3kW | 4kW | 6kW |

| Pipe Processing Range(Round Tube) | φ20-φ350mm |

| Pipe Processing Range(Square Tube) | 20×20-350×350mm |

| Max Speed | 60 m/min |

| Positioning Accuracy | ±0.05 |

| Repeated Positioning Accuracy | ±0.03mm |

| Max chuck Speed | 60r/min |

| Max Acceleration | 0.6G |

| Max Table Load | 1000KG |

Our Bevel Fibre Laser Tube Cutting System stands as a pinnacle of precision and efficiency in pipe-cutting technology.

With its capability to execute flawless 45° bevel cuts and support various pipe shapes through pneumatic auto-clamping chucks, it offers unparalleled operational efficiency.

This machine is a vital asset for sectors needing advanced bevel cutting, streamlining processes, and improving joint quality in applications. Its introduction marks a significant leap forward in the fabrication and construction industries, ensuring high-quality outcomes with reduced processing time.